Introduction

In pharmaceutical manufacturing, utility gases like compressed air must meet stringent quality standards to ensure product safety and regulatory compliance. Yet many facilities, especially new or expanding ones, lack fully developed qualification programs for these critical systems. This article presents a real-world case study involving a pharmaceutical company in Bethlehem, PA, where we implemented a comprehensive utility validation program, investigated and resolved hydrocarbon contamination, and supported the qualification of associated systems including purified water, cleaning validation, and environmental monitoring, through to routine monitoring support.

Project Overview

Facility Type: Solid Oral Dosage Pharmaceutical Manufacturing

Location: Bethlehem, PA

Scope:

- Compressed Air Qualification

- Hydrocarbon Troubleshooting & Remediation

- Cleaning Validation for Equipment

- Purified Water System Qualification

PART 1 – Gas Qualification & Hydrocarbon Remediation

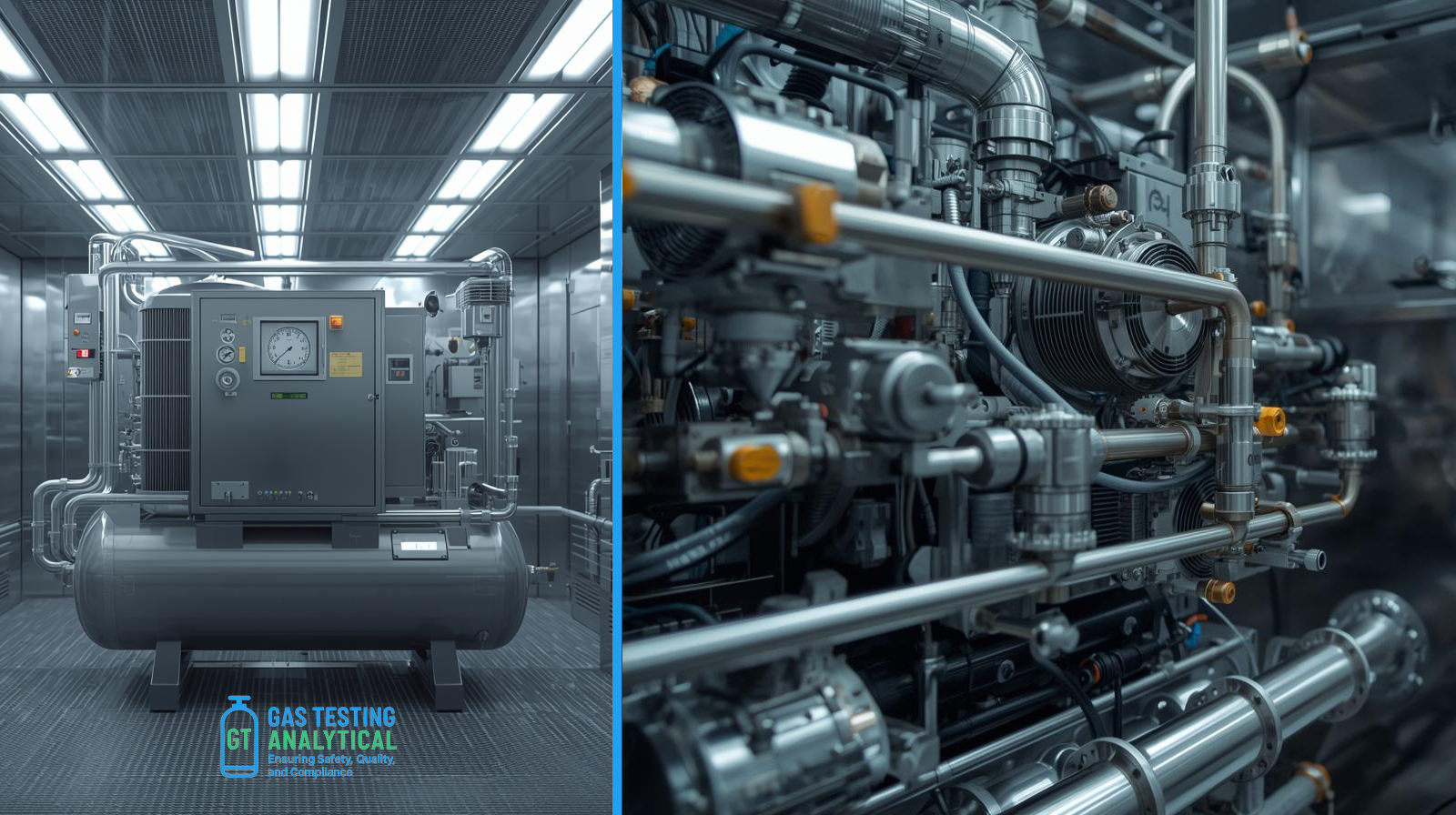

Trouble in the Lines: Compressed Air Validation and Hydrocarbon Remediation at a New Pharmaceutical Facility

Intro:

Compressed air is often overlooked during facility commissioning until it becomes a liability. At a new facility in Bethlehem, PA, we helped launch their compressed air validation program, only to uncover hydrocarbon contamination that could jeopardize product safety and compliance. Here’s how we investigated and resolved the issue—and built a sustainable monitoring program from scratch.

Baseline Testing Reveals Hydrocarbon Risk

During early startup, the facility engaged us to support compressed air validation in alignment with ISO 8573-1 and USP <1231>. We began with baseline testing at multiple points of use, focusing on:

- Total Hydrocarbons (THC)

- Oil Aerosols

- Moisture/Dew Point

- Particulates

Problem: THC levels exceeded acceptable thresholds for ISO Class 1. While water and particle counts were within spec, hydrocarbons posed an immediate risk.

Root Cause Investigation:

Possible hydrocarbon sources were investigated:

- Residual hydrocarbons from installation

-

- Lines were flushed by opening the lines overnight multiple times.

- Process owners considered flushing with solvent and dry nitrogen

- Lines were flushed by opening the lines overnight multiple times.

- Oil-lubricated legacy compressors

-

- Not applicable as this was a new facility with oil-free compressors.

- Inadequate downstream filtration

-

- Additional filters were considered for POU and other areas

- Specification vs methodology: Method called for hydrocarbon testing when analyte of interest was oil mist. Additional testing confirmed no oil mist, but hydrocarbon contamination could not be ignored.

- Air sampling at intake and compressed air supply confirmed hydrocarbons were being introduced upstream and were related to air quality at the source.

A combination of coalescing and carbon filtration upgrades were implemented. We worked closely with engineering to redesign flow paths and minimize contamination traps.

Resolution and Requalification

Following system upgrades:

- Piping was flushed and dried

- Retesting confirmed remediation of hydrocarbon contamination

- SOPs for compressed air monitoring were authored and implemented

- A recurring sampling plan was initiated and tied to facility QA systems

Why This Matters

Compressed air is a critical process utility, but one often treated as an afterthought. This project serves as a reminder: gas qualification must be proactive, data-driven, and aligned with evolving regulatory expectations.

Stay tuned for Part 2, where we’ll walk through purified water system qualification—another essential utility that can make or break compliance in a new build.